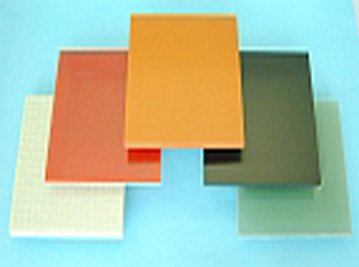

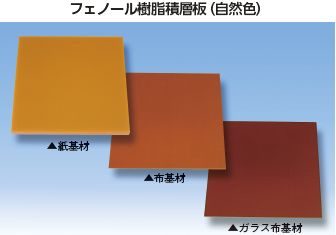

Paper-based phenolic laminated sheets

Paper-based phenolic laminated sheets are the most commonly seen laminates, as well as having the widest applications and largest usage.

Paper-based phenolic laminated sheets made in Taiwan have excellent electrical, mechanical properties and are easy to process. We only use high-quality bleached kraft paper and/or cotton linter paper as reinforcement. The phenolic resin used as a binder is produced with highly purified and fully synthetic petrol-chemical raw materials.

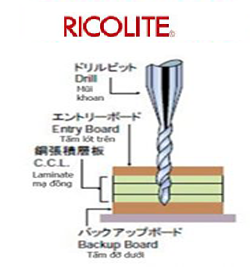

Traditionally, Taiwan’s paper-based phenolic laminated sheets have few categories, depending on users’ processing methods. Namely, hot-punch, warm-punch, cold-punch and non-punchable. For those that are punch-able, please refer to the table below for pre-heating conditions where applicable. The so-called “thick” non-punchable sheets can be processed by various methods, such as sawing, planing, milling, lathing, grinding, and drilling.

Table of Punching Temperature

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cotton fabric-based phenolic laminated sheets

Cotton fabric-based phenolic laminated sheets are manufactured by modified phenolic resin as a binder and pure cotton fabric as reinforcement. They have exceptionally good heat resistance and will not creep under high-temperature conditions.

Cotton fabric-based phenolic laminated sheets made in Taiwan do not only have excellent mechanical properties, but their toughness and high impact strength allow the fabrication of gears/cogs and pulleys. These types of gears and pulleys are noise-reducing, hard-wearing, and able to prolong the life of machinery.

SDL-4060 and SDC-5055 have better moisture resistance and resistance to wear. They are ideal for applications requiring both electrical properties and wear resistance, such as insulating washers for micro-motors and leaves for pneumatic tools.

Cotton fabric-based phenolic laminated sheets have very similar fabrication characteristics as its paper-based sheets. Please refer to the table below for pre-heating conditions where applicable. The so-called “thick” non-punchable sheets can also be processed by various methods, such as sawing, planing, milling, lathing, grinding, and drilling.

Table of Punching Temperature

USE ELECTRONICS VIETNAM CO., LTD

5 FLOOR – EUROWINDOW COMPLEX BUILDING – 27 TRAN DUY HUNG – CAU GIAY – HA NOI

TEL: +84 24 3581 0018

EMAIL: INFO@USEEVN.COM

VI

VI JP

JP 中文 (台灣)

中文 (台灣)