Defination of wave soldering

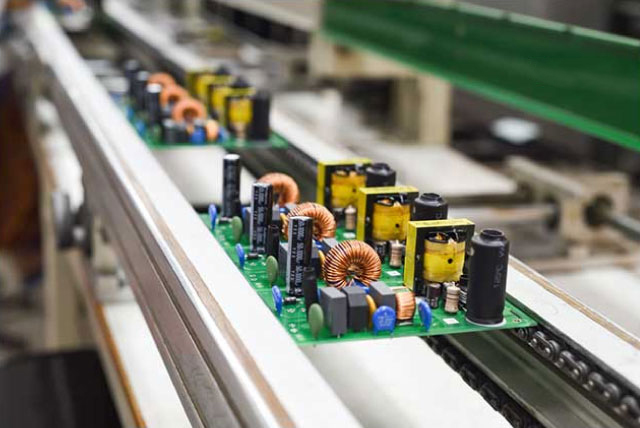

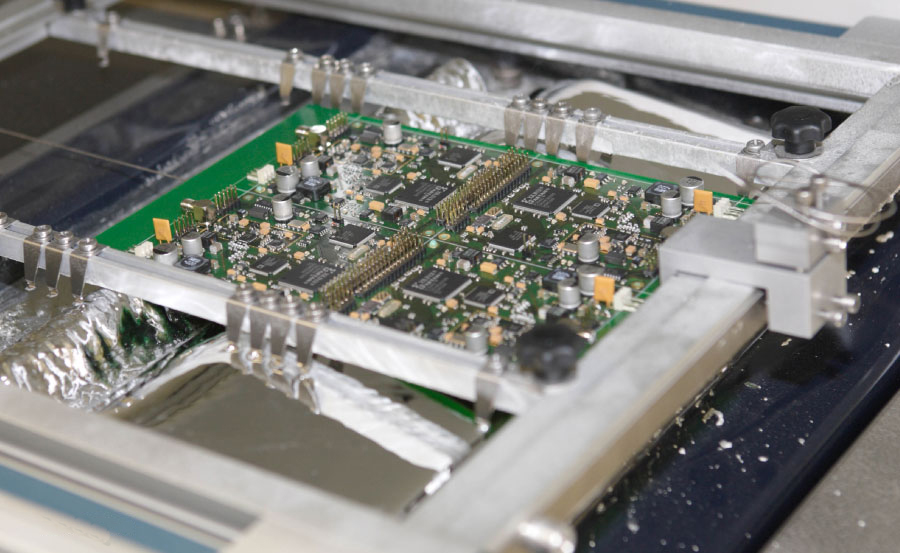

Wave soldering is a large-scale soldering process by which electronic components are soldered to a printed circuit board (PCB) to form an electronic assembly. The name is derived from the use of waves of molten solder to attach metal components to the PCB. The process uses a tank to hold a quantity of molten solder; the components are inserted into or placed on the PCB and the loaded PCB is passed across a pumped wave or waterfall of solder. The solder wets the exposed metallic areas of the board (those not protected with solder mask, a protective coating that prevents the solder from bridging between connections), creating a reliable mechanical and electrical connection. The process is much faster and can create a higher quality product than manual soldering of components. Wave soldering is used for both through-hole and surface mount printed circuit assemblies. In the case of surface mount, components are glued by the locator to the printed circuit board surface before being run through a wave of molten solder.

Wave soldering is used for both through-hole and surface mount printed circuit assemblies. In the case of surface mount, components are glued by the locator to the printed circuit board surface before being run through a wave of molten solder.

Wave soldering process

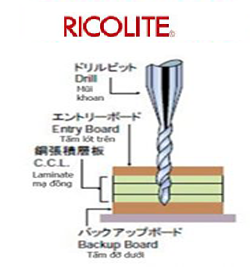

Wave welding is the heart of the machine and the center of the welding process. The soldering waves include main wave and chip wave or chaotic. The main wave in a welding process is usually a wave with flow controlled flow at the nozzle. During a main wave N2 welding process. This is an “A” wave called the coN2tour. It is the process of using inert gas during welding to increase the permeability welding process. This helps reduce the amount of flux required and gives nice shiny welds. Chip waves or chaotic waves are often used when there are components attached to the PCB bottom. The chaotic fluctuations of chip waves help to break up air bubbles generated from flux. In addition to that, it helps push liquid fillings around the component pins.

Wave height is an important parameter because it affects the dwell time in the welding tank and the exit from the welding tank. As a general rule the wave height should be near half the thickness of the PCB, when the PCB enters the soldering wave. The temperature of the wave is usually arranged between 470oF and 500oF.

Chip waves or chaotic waves are often used when there are components attached to the PCB bottom. The chaotic fluctuations of chip waves help to break up air bubbles generated from flux. In addition to that, it helps push liquid fillings around the component pins.

Wave height is an important parameter because it affects the dwell time in the welding tank and the exit from the welding tank. As a general rule the wave height should be near half the thickness of the PCB, when the PCB enters the soldering wave. The temperature of the wave is usually arranged between 470oF and 500oF.

VI

VI JP

JP 中文 (台灣)

中文 (台灣)