The concept of Surface-mount technology (SMT)

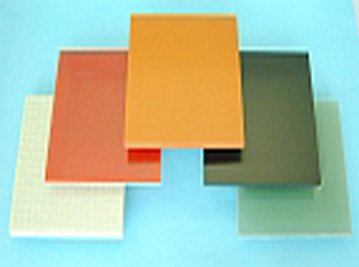

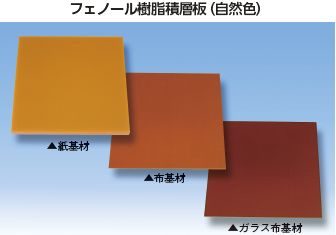

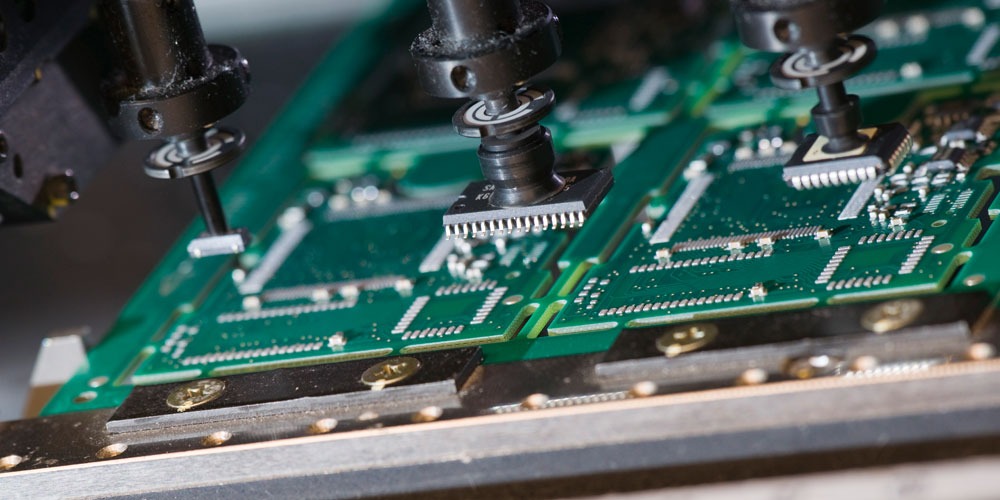

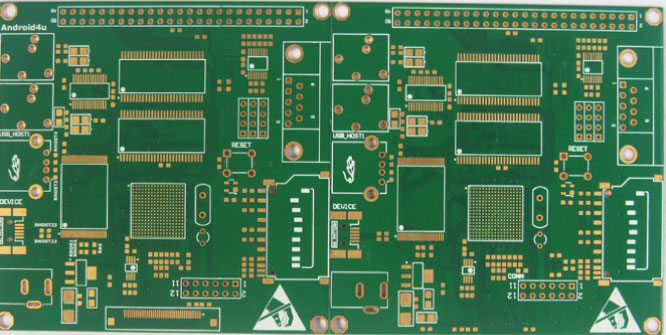

Welding technology of surface components – SMT. This is a method of attaching electronic components directly onto the surface of the board (PCB). The electronic component dedicated to this technology is called SMD. Currently, SMT has replaced most of the technology of packaging PCB components through holes. Accordingly electronic components are fixed on the PCB surface. They are used by piercing method and soldering through hot lead tanks. SMT technology was developed in the 1960s. It was then widely applied in the late 1980s. IBM Corporation (USA) is a pioneer in this technology.

Electronic components are machined to attach an additional piece of metal to both ends. This is designed so that they can be soldered directly onto the printed circuit surface. The component size has been greatly reduced. The mounting of components on both sides of the PCB makes SMT technology more common. Compared with component mounting technology by hole punching. This allows for an increase in component density. Typically, each component is fixed on the printed circuit board surface with a very small lead coating area. On the other side of the component PCB are also fixed only with a solder paste. As a result, the physical size of components is decreasing. SMT technology has a high degree of automation. They do not require a lot of labor and especially increase production capacity.

SMT technology was developed in the 1960s. It was then widely applied in the late 1980s. IBM Corporation (USA) is a pioneer in this technology.

Electronic components are machined to attach an additional piece of metal to both ends. This is designed so that they can be soldered directly onto the printed circuit surface. The component size has been greatly reduced. The mounting of components on both sides of the PCB makes SMT technology more common. Compared with component mounting technology by hole punching. This allows for an increase in component density. Typically, each component is fixed on the printed circuit board surface with a very small lead coating area. On the other side of the component PCB are also fixed only with a solder paste. As a result, the physical size of components is decreasing. SMT technology has a high degree of automation. They do not require a lot of labor and especially increase production capacity.

Advantages when using SMT technology:

- Smaller components.

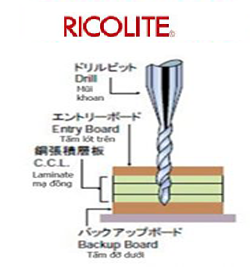

- Very little hole is needed to make during PCB manufacturing.

- The assembly process is simpler.

- Small errors encountered during packaging are corrected automatically

- Components can be mounted on both sides of the board.

- Reduces the impedance and resistance of the exposed lead layer (increases the efficiency of high frequency components). The feature is more durable under shock and vibration.

- Component prices for SMT technology are cheaper than components prices for piercing technology.

- Unwanted high frequency (RF) effects occur less frequently when using SMT technology. This facilitates the prediction of component characteristics.

SMT technology was born, gradually replacing the hole-through packaging technology. This does not mean that SMT is perfectly ideal. The SMT manufacturing process is more elaborate than the hole-through packaging technology. The initial investment cost is relatively large and time consuming in installing the system.

Due to the small component size, the resolution of the components on the board is very high. This makes the research and deployment of this technology manual will make the failure rate great and costly.

SMT technology was born, gradually replacing the hole-through packaging technology. This does not mean that SMT is perfectly ideal. The SMT manufacturing process is more elaborate than the hole-through packaging technology. The initial investment cost is relatively large and time consuming in installing the system.

Due to the small component size, the resolution of the components on the board is very high. This makes the research and deployment of this technology manual will make the failure rate great and costly.

VI

VI JP

JP 中文 (台灣)

中文 (台灣)